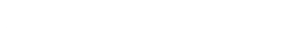

General Structured PackingREGULAR PACKINGS

Mesh MC-Y PACK:BY-W500X/W700Y/W1000Y

BY-W500YX/W700Y/W1000Y are mesh type of special structured wire mesh.These are achieving a low pressure drop and high NTSM compared with sheet type.

These are appropriate for the process required NTS under decompression.

【CHARACTERISTICS】

●High NTSM

●Pressure drop single theoretical step —

0.1 to 0.5mmHg

●Proper liquid load range — 0.05 to 20m³/m²H

●Maximum F factor — BY-W500X :2.5

BY-W700Y :1.8

BY-W1000Y:1.0

| Name | Surface m²/m³ |

Void space % |

Weight kg/m³ |

Height per mm |

Substance |

|---|---|---|---|---|---|

| BY-W500X | 500 | 94 | 266 | 175 | Wire mesh |

| BY-W700Y | 700 | 91 | 370 | 145 | Wire mesh |

| BY-W1000Y | 1000 | 88 | 531 | 145 | Wire mesh |

Bulk Density at a material specific gravity 7.93 for stainless steel type 304.

SUS304, SUS316L, Copper

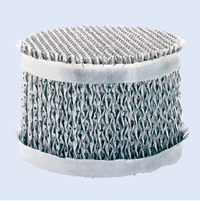

Sheet MC-Y PACK

| Parameter | BY- M64X |

BY- M64Y |

BY- 125X |

BY- M125Y |

BY- M200X |

BY- M200Y |

BY- M250X |

BY- M250Y |

|---|---|---|---|---|---|---|---|---|

| Specific Area m²/m³ |

64 | 125 | 200 | 250 | ||||

| Void space % |

99.5 | 99.5 | 99.2 | 99.2 | 98.8 | 98.8 | 98.5 | 98.5 |

| MIN liquid load m³/m²/hr |

0.5 | 0.5 | 0.5 | 0.5 | 0.2 | 0.2 | 0.2 | 0.2 |

| MAX liquid load m³/m²/hr |

100 | 100 | 100 | 100 | 100 | 80 | 75 | 80 |

| Max F factor m/s[kg/m³]1/2 |

4.2 | 3.7 | 4.0 | 3.5 | 3.7 | 3.2 | 3.4 | 3.0 |

| Standard HETP mm |

2000 | 1500 | 1200 | 800 | 700 | 500 | 550 | 450 |

|

Weight kg/m³ |

40 | 40 | 64 | 64 | 96 | 84 | 105 | 105 |

| Height per Element mm |

200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| MAX Packing Height per Layer *mm | 8000 | 8000 | 8000 | 8000 | 7000 | 7000 | 6000 | 6000 |

| Parameter | BY- M350X |

BY- M350Y |

BY- M500X |

BY- M500Y |

BY- M750Y |

|||

|---|---|---|---|---|---|---|---|---|

| Specific Area m²/m³ |

350 | 500 | 750 | |||||

| Void space % |

98 | 98 | 97.2 | 97.2 | 95.9 | |||

| MIN liquid load m³/m²/hr |

0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |||

| MAX liquid load m³/m²/hr |

40 | 30 | 25 | 20 | 10 | |||

| Max F factor m/s[kg/m³]1/2 |

2.8 | 2.5 | 2.3 | 2.0 | 1.6 | |||

| Standard HETP mm |

430 | 360 | 370 | 280 | 230 | |||

| Weight kg/m³ |

144 | 144 | 210 | 210 | 300 | |||

| Height per Element mm |

200 | 200 | 200 | 200 | 200 | |||

| MAX Packing Height per Layer *mm | 4500 | 4500 | 3500 | 3500 | 3000 | |||

Hastelloy, Aluminum, copper, Nickel

※3000mm when using a tower with 300φor less diameter

Bulk Density at a material specific gravity 7.93 for stainless steel type 304.

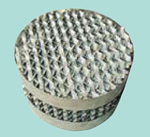

Ceramic MC-C PACK【Ceramic Structured Packing】

| Parameter | 125X | 125Y | 160X | 250X | 250Y | 350Y | 450X | 450Y | 700Y |

|---|---|---|---|---|---|---|---|---|---|

| Specific Area m²/m³ m²/m³ |

125 | 125 | 160 | 250 | 250 | 350 | 450 | 450 | 700 |

| Void space % |

90 | 90 | 85 | 80 | 80 | 78 | 72 | 72 | 68 |

| Oblique Angle ° |

45 | 45 | 30 | 45 | 45 | 30 | 45 | 45 | |

| Liquid Load m³/m²/hr |

0.2~100 | 0.2~100 | 0.2~70 | 0.2~65 | 0.2~50 | 0.2~30 | 0.2~20 | 0.2~15 | 0.2~7 |

| MAX F factor m/s[kg/m³]1/2 |

3.2 | 3.0 | 2.7 | 2.8 | 2.4 | 2.0 | 1.7 | 1.5 | 1.2 |

| NTSM l/m |

1.5 | 1.7 | 1.9~2.2 | 2.3~2.7 | 2.5~3.0 | 2.8~3.2 | 3~4 | 3.5 | 6~8 |

| Packing Density kg/m³ |

320 | 320 | 370 | 420 | 420 | 500 | 550 | 550 | 730 |

| Sheet Pressure mm |

2.0~3.0 | 2.0~3.0 | 2.0~2.5 | 1.7~2.0 | 1.7~2.0 | 1.3~1.6 | 1.0~1.2 | 1.0~1.2 | 0.9~1.1 |

| Height per Element mm |

150 | 150 | 150 | 100 | 100 | 100 | |||

※Ceramic plates manufactured can be porous or non-porous ones.

Bulk Density at a specific gravity 2.29 for ceramic material